- If you download this document, you will be lost Beer

Technology "Sky Activ" Mazda has the task of maximizing the potential of the internal combustion engine before you have to make use of electric motor technology. Also for this reason, while the other car manufacturers developing EV and Hybrid vehicles, Mazda focused on developing unique technologies to develop the potential of the internal combustion engine.

According to Mazda, despite constantly being improved for hundreds of years, but the current combustion engine only advantage from 20% to 30% of the energy contained in the fuel turns into kinetic energy to operate the wheel car. The rest either are not fully burned or lost in vain as heat. Technology "Sky Activ" Mazda has the task of maximizing the potential of the internal combustion engine before you have to make use of electric motor technology. Also for this reason, while the other car manufacturers developing EV and Hybrid vehicles, Mazda focused on developing unique technologies to develop the potential of the internal combustion engine.

1. SKYACTIV engine has the highest compression ratio of 14: 1

The compression ratio of the 4-stroke internal combustion engine is the ratio between the cylinder volume at the end of intake stroke, when the plunger at the lowest point (bottom dead center, DCD), compared to the combustion chamber volume at the end of the compression stroke, when piston culminated (top dead center, DCT). In other words, the ratio between air volume and the volume of gas to be loaded after compression. In the classic engine, the ratio is 8: 1 (8 parts air volume air, compressed to 1 share). The higher the compression ratio, the more powerful engine power. In past decades, the automotive manufacturers are seeking to increase the compression ratio of the engine to increase performance and fuel economy.

Naturally aspirated engine, the compression ratio is only 8: 1, 9: 1, when the technology is enhanced with direct fuel injection, the compression ratio of the internal combustion engine has increased to 10: 1, a few the engine has achieved 12: 1. And this is the threshold of another cell manufacturers did not pass because if the increase will occur phenomenon engine "knock" or was "thrilled" by the spontaneous combustion of fuel before the plunger up to DCT and barely a spark plug cheat. Occurs when the fuel burns unwanted early, engine power will be reduced. Mazda is the only carmaker in the world to overcome the phenomenon of air before combustion gas ignited by a spark, and increased the compression ratio to 14: 1. Mazda recipes help do this?

The automobile manufacturers have discovered the phenomenon of spontaneous combustion air before gas ignition spark plugs depends on the following factors: compression ratio, air temperature and gas. So to increase the compression ratio needs to reduce the temperature of the compressed air and gas in the period.

In the compression stroke, the air-gas pressure increases, the temperature will also increase. For example, in the air conditioning temperature is 97.5 degrees period-end loader C. When compression of 10: 1, the temperature will increase by 70 degrees. At the piston in the explosion DCT prepared pan, the temperature will be 167.5 degrees.

At the combustion stroke, temperature and pressure spike to push the plunger down to DCD. In this process, decreasing the temperature down to 750 degrees C. This is the temperature of the exhaust.

In theory, the engine compression ratio of 10: 1, final exit will remain in the 10% emissions combustor exit. In the intake stroke, 10% of residual exhaust temperature of 750 degrees C with 90% to the air conditioning has an average temperature of 25 degrees Celsius, causing the temperature at the top of the compression stroke carburetor is [750 + (9 x 25) ]: 10 = 97.5 degrees C. as the piston moves up expressway increasing pressure, air conditioning will increase to 70 degrees C, the temperature at this time would be 167.5 degrees.

But in fact, this time the temperature up to 200 degrees C. When At this temperature, air conditioning can fire at any time, without sparks, causing fire sooner than expected. Explain the difference between the theoretical temperature and the actual Mazda engineers have identified the cause of the residual emissions in the cylinder at the exit end of the period is not one that is 1.5 or higher , has increased the temperature: [(750 x 1.5) + (9 x 25)]: 10.5 = 128.57 degrees celsius, the temperature plus 70 degrees C increases under stress, causing the temperature to to 200 degrees C.

Cause of exhaust gas flow in the combustion chamber more the theory is due to the piston exhaust before acting on the outlet of the plunger on duty exhaust. Mazda minimize pressure on the plunger before the plunger exit after exit exhaust system with 4-2-1 (4-2-1 exhaust system).

4-2-1 exhaust systems (4-2-1 exhaust system)

Full name is 4-2-1-3 exhaust system. This is the 4 cylinders are numbered in the order of succession to the exhaust stroke. Below is a diagram of the 4-stroke 4-cylinder operation.

1 Cylinders Cylinders Cylinders No. 2 No. 3 No. 4 Cylinders

Load Discharge period 1 Compression Explosion

Compression Load Discharge period 2 Explosion

Compression Load Discharge Explosive United 3

Explosion Load Discharge 4 Compress States

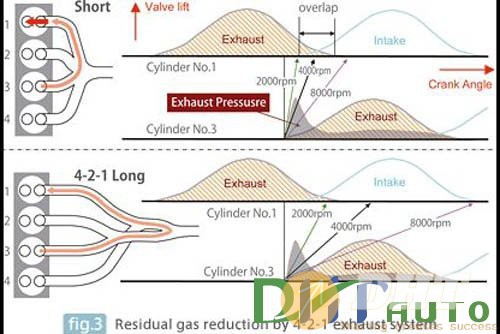

For example, in the short exhaust system, in period 3, cylinder No. 1 in the state of discharge, the pressure in the exhaust will rise dramatically and then fell slowly exhaust pace. To period 4, cylinder No. 1 will switch to smoking status and number 3 cylinder will exit status. But this time the pressure of the exhaust gas cylinder 1 has an impact on the drainage tube in cylinder No. 3 exhaust makes one part should escape to return to the combustion chamber.

To fix, 4-2-1 exhaust system with larger exhaust pipes and longer, is arranged so that passage between the exhaust pipe connecting 4-2, 2-1, 1-3, 3-4 is long most (over 60 cm). Exhaust passage between cylinders 2 and 3 is short but this is not a 2 cylinder exhaust consecutively. (Photo 3, left).

The impact of the drainage capacity in the cylinder before the cylinder after depending on engine revs. Typically, the impact of the discharge pressure in the cylinder No. 1 to No. 3 cylinder (see photo). In old-style exhaust system pressures up during the rotation of the motor from 2,000 to 8,000 revolutions / minute (rpm). For the 4-2-1 exhaust system, the maximum pressure of the exhaust gas discharge cylinder before the cylinder exhaust impact on later in the range from 0 to 2,000 rpm rev / min, the engine rpm is less operate. At higher engine speed of 2,000 rev / min, is about regular activities rpm, pressure to reduce to a minimum (see photo 3). Thus, the technology enables 4-2-1 exhaust hot air out the maximum air temperature reducing gas in the intake stroke.

In short, 4-2-1 exhaust system with larger cross section to reduce the pressure, the pressure longer to exhaust affects the next cylinder to slow down, do not fall at the right time of the exhaust valve is opened . The prolongation of the exhaust pipe also helps to reduce the temperature of the exhaust gas before contact with the catalyst in the exhaust filter, making the life of the catalyst is prolonged and enhanced effectiveness of the removal of the toxic gases.

According to Mazda, raising the compression ratio has contributed to a 15% increase in fuel efficiency and 15% higher motor torque when operating at slow and medium revs.

Artwork of explosion protection technology soon unintended:

Multiple fuel injection nozzle

To extinguish one fire, firefighters use measures to prevent burning plants exposed to oxygen in the air with CO2 or foam soap. But the most common methods is to lower the temperature of water spraying fire and environmental materials fire as many nozzles, the faster the fire was extinguished. Fire with water to apply the rule, while 1 gram of water vapor (moving from liquid to gaseous state) will absorb 540 calories, as the temperature dropped quickly. Gasoline, too, when gasoline moved from liquid to gaseous state absorbs heat and reduces the temperature surroundings.

Similar to how the firefighters extinguish the fire by lowering the temperature sprinklers. Automobile manufacturers lower temperature combustion chamber by injection technology directly into the raw nhie cylinder. As a result, the fuel injection system directly, the automobile manufacturer has increased the compression ratio is 8: 1 to 11: 1 and 12: 1.

But technology's direct fuel injection Mazda completely different from other automotive manufacturers. While other car manufacturers to use the technology fueling stratified (Stratified charge), Mazda uses technology fueling homogeneous (Homogeneous Charge). The difference in the two technologies are: Technology stratified fuel injection in the compression stroke fuel injection in mid-cylinder, most close to the spark plug. Peace will be divided into two classes: near the spark plug, higher fuel concentrations; Stay away from spark plugs, carburetor fuel poverty. The result is that when the ignition, carburetor was almost completely burnt.

In the fuel injection technology SKYACTIV uniform, gasoline is injected into the nozzles fed by multiple nozzle (multi-point fuel injection), petrol-sized dust particles a few millionths of a millimeter formula (mu) rapid evaporation, absorption heat and air conditioning to become homogeneous. Technology fueling nozzles identified with multiple showerheads lowers combustion temperature. Along with the 4-2-1 exhaust system helps the engine achieve Mazda's SkyActv compression ratio of 14: 1. The highest figure in the world today for gasoline engines.

Piston concave

With perceived by the senses, I feel explosive reaction of the air fuel mixture occurs instantly, as soon as the spark plug emit sparks. In fact, the response of fire spread from location to spark more remote areas in the combustion chamber. Speed of fire spread is even slower than the speed of movement of the plunger from DCT to DCD. When the engine is operating at high speeds, unburnt fuel could not be released into the environment. To overcome this drawback, in naturally aspirated engines modified ignition before the piston reaches the expressway this solution while bringing fuel efficiency, but not high.

For added peace of being burned, many automobile manufacturers to add the solution to the fuel injection stratified gasoline vapor concentration near the spark plug. Mazda does not use fuel stratified injection, instead use pistons with recessed area in the middle to force air into the air near the spark plugs spark. (Photo 4) The result of this solution has increased the fuel efficiency of 15%.

According to Mazda, despite constantly being improved for hundreds of years, but the current combustion engine only advantage from 20% to 30% of the energy contained in the fuel turns into kinetic energy to operate the wheel car. The rest either are not fully burned or lost in vain as heat. Technology "Sky Activ" Mazda has the task of maximizing the potential of the internal combustion engine before you have to make use of electric motor technology. Also for this reason, while the other car manufacturers developing EV and Hybrid vehicles, Mazda focused on developing unique technologies to develop the potential of the internal combustion engine.

1. SKYACTIV engine has the highest compression ratio of 14: 1

The compression ratio of the 4-stroke internal combustion engine is the ratio between the cylinder volume at the end of intake stroke, when the plunger at the lowest point (bottom dead center, DCD), compared to the combustion chamber volume at the end of the compression stroke, when piston culminated (top dead center, DCT). In other words, the ratio between air volume and the volume of gas to be loaded after compression. In the classic engine, the ratio is 8: 1 (8 parts air volume air, compressed to 1 share). The higher the compression ratio, the more powerful engine power. In past decades, the automotive manufacturers are seeking to increase the compression ratio of the engine to increase performance and fuel economy.

Naturally aspirated engine, the compression ratio is only 8: 1, 9: 1, when the technology is enhanced with direct fuel injection, the compression ratio of the internal combustion engine has increased to 10: 1, a few the engine has achieved 12: 1. And this is the threshold of another cell manufacturers did not pass because if the increase will occur phenomenon engine "knock" or was "thrilled" by the spontaneous combustion of fuel before the plunger up to DCT and barely a spark plug cheat. Occurs when the fuel burns unwanted early, engine power will be reduced. Mazda is the only carmaker in the world to overcome the phenomenon of air before combustion gas ignited by a spark, and increased the compression ratio to 14: 1. Mazda recipes help do this?

The automobile manufacturers have discovered the phenomenon of spontaneous combustion air before gas ignition spark plugs depends on the following factors: compression ratio, air temperature and gas. So to increase the compression ratio needs to reduce the temperature of the compressed air and gas in the period.

In the compression stroke, the air-gas pressure increases, the temperature will also increase. For example, in the air conditioning temperature is 97.5 degrees period-end loader C. When compression of 10: 1, the temperature will increase by 70 degrees. At the piston in the explosion DCT prepared pan, the temperature will be 167.5 degrees.

At the combustion stroke, temperature and pressure spike to push the plunger down to DCD. In this process, decreasing the temperature down to 750 degrees C. This is the temperature of the exhaust.

In theory, the engine compression ratio of 10: 1, final exit will remain in the 10% emissions combustor exit. In the intake stroke, 10% of residual exhaust temperature of 750 degrees C with 90% to the air conditioning has an average temperature of 25 degrees Celsius, causing the temperature at the top of the compression stroke carburetor is [750 + (9 x 25) ]: 10 = 97.5 degrees C. as the piston moves up expressway increasing pressure, air conditioning will increase to 70 degrees C, the temperature at this time would be 167.5 degrees.

But in fact, this time the temperature up to 200 degrees C. When At this temperature, air conditioning can fire at any time, without sparks, causing fire sooner than expected. Explain the difference between the theoretical temperature and the actual Mazda engineers have identified the cause of the residual emissions in the cylinder at the exit end of the period is not one that is 1.5 or higher , has increased the temperature: [(750 x 1.5) + (9 x 25)]: 10.5 = 128.57 degrees celsius, the temperature plus 70 degrees C increases under stress, causing the temperature to to 200 degrees C.

Cause of exhaust gas flow in the combustion chamber more the theory is due to the piston exhaust before acting on the outlet of the plunger on duty exhaust. Mazda minimize pressure on the plunger before the plunger exit after exit exhaust system with 4-2-1 (4-2-1 exhaust system).

4-2-1 exhaust systems (4-2-1 exhaust system)

Full name is 4-2-1-3 exhaust system. This is the 4 cylinders are numbered in the order of succession to the exhaust stroke. Below is a diagram of the 4-stroke 4-cylinder operation.

1 Cylinders Cylinders Cylinders No. 2 No. 3 No. 4 Cylinders

Load Discharge period 1 Compression Explosion

Compression Load Discharge period 2 Explosion

Compression Load Discharge Explosive United 3

Explosion Load Discharge 4 Compress States

For example, in the short exhaust system, in period 3, cylinder No. 1 in the state of discharge, the pressure in the exhaust will rise dramatically and then fell slowly exhaust pace. To period 4, cylinder No. 1 will switch to smoking status and number 3 cylinder will exit status. But this time the pressure of the exhaust gas cylinder 1 has an impact on the drainage tube in cylinder No. 3 exhaust makes one part should escape to return to the combustion chamber.

To fix, 4-2-1 exhaust system with larger exhaust pipes and longer, is arranged so that passage between the exhaust pipe connecting 4-2, 2-1, 1-3, 3-4 is long most (over 60 cm). Exhaust passage between cylinders 2 and 3 is short but this is not a 2 cylinder exhaust consecutively. (Photo 3, left).

The impact of the drainage capacity in the cylinder before the cylinder after depending on engine revs. Typically, the impact of the discharge pressure in the cylinder No. 1 to No. 3 cylinder (see photo). In old-style exhaust system pressures up during the rotation of the motor from 2,000 to 8,000 revolutions / minute (rpm). For the 4-2-1 exhaust system, the maximum pressure of the exhaust gas discharge cylinder before the cylinder exhaust impact on later in the range from 0 to 2,000 rpm rev / min, the engine rpm is less operate. At higher engine speed of 2,000 rev / min, is about regular activities rpm, pressure to reduce to a minimum (see photo 3). Thus, the technology enables 4-2-1 exhaust hot air out the maximum air temperature reducing gas in the intake stroke.

In short, 4-2-1 exhaust system with larger cross section to reduce the pressure, the pressure longer to exhaust affects the next cylinder to slow down, do not fall at the right time of the exhaust valve is opened . The prolongation of the exhaust pipe also helps to reduce the temperature of the exhaust gas before contact with the catalyst in the exhaust filter, making the life of the catalyst is prolonged and enhanced effectiveness of the removal of the toxic gases.

According to Mazda, raising the compression ratio has contributed to a 15% increase in fuel efficiency and 15% higher motor torque when operating at slow and medium revs.

Artwork of explosion protection technology soon unintended:

Multiple fuel injection nozzle

To extinguish one fire, firefighters use measures to prevent burning plants exposed to oxygen in the air with CO2 or foam soap. But the most common methods is to lower the temperature of water spraying fire and environmental materials fire as many nozzles, the faster the fire was extinguished. Fire with water to apply the rule, while 1 gram of water vapor (moving from liquid to gaseous state) will absorb 540 calories, as the temperature dropped quickly. Gasoline, too, when gasoline moved from liquid to gaseous state absorbs heat and reduces the temperature surroundings.

Similar to how the firefighters extinguish the fire by lowering the temperature sprinklers. Automobile manufacturers lower temperature combustion chamber by injection technology directly into the raw nhie cylinder. As a result, the fuel injection system directly, the automobile manufacturer has increased the compression ratio is 8: 1 to 11: 1 and 12: 1.

But technology's direct fuel injection Mazda completely different from other automotive manufacturers. While other car manufacturers to use the technology fueling stratified (Stratified charge), Mazda uses technology fueling homogeneous (Homogeneous Charge). The difference in the two technologies are: Technology stratified fuel injection in the compression stroke fuel injection in mid-cylinder, most close to the spark plug. Peace will be divided into two classes: near the spark plug, higher fuel concentrations; Stay away from spark plugs, carburetor fuel poverty. The result is that when the ignition, carburetor was almost completely burnt.

In the fuel injection technology SKYACTIV uniform, gasoline is injected into the nozzles fed by multiple nozzle (multi-point fuel injection), petrol-sized dust particles a few millionths of a millimeter formula (mu) rapid evaporation, absorption heat and air conditioning to become homogeneous. Technology fueling nozzles identified with multiple showerheads lowers combustion temperature. Along with the 4-2-1 exhaust system helps the engine achieve Mazda's SkyActv compression ratio of 14: 1. The highest figure in the world today for gasoline engines.

Piston concave

With perceived by the senses, I feel explosive reaction of the air fuel mixture occurs instantly, as soon as the spark plug emit sparks. In fact, the response of fire spread from location to spark more remote areas in the combustion chamber. Speed of fire spread is even slower than the speed of movement of the plunger from DCT to DCD. When the engine is operating at high speeds, unburnt fuel could not be released into the environment. To overcome this drawback, in naturally aspirated engines modified ignition before the piston reaches the expressway this solution while bringing fuel efficiency, but not high.

For added peace of being burned, many automobile manufacturers to add the solution to the fuel injection stratified gasoline vapor concentration near the spark plug. Mazda does not use fuel stratified injection, instead use pistons with recessed area in the middle to force air into the air near the spark plugs spark. (Photo 4) The result of this solution has increased the fuel efficiency of 15%.

Last edited by a moderator: