- If you download this document, you will be lost 3225 Beer

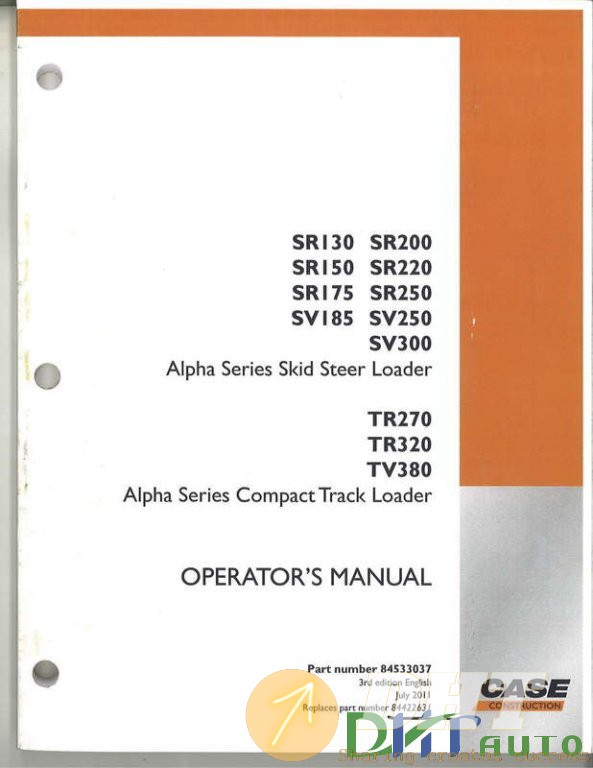

CASE SKID STEER LOADER ALPHA SR130, SR150, SR175, SV185, SV300, SV250, SR250, SR220, SR200, TR270, TR320, TV380 OPERATORS & SERVICE MANUAL

Code:

Brand: Case

Product Code: Case

Availability: In Stock

01.2013 / All Regions / 1 CD / Windows 10, Windows 8, Windows 7, Windows Vista, Windows XP / 32 & 64 bit

CASE Skid Steer Loader Alpha Series SR130, SR150, SR175, SV185, SV300, SV250, SR250, SR220, SR200

Alpha Series Compact Track Loader TR270, TR320, TV380

Operators Manual, Service & Repair Manual, Wiring diagrams, Circuits, Technical Data, Maintenance, Troubleshooting, Specifications and other

Languages: English

Code:

SERVICE MANUAL

INTRODUCTION

HYDRAULIC, PNEUMATIC, ELECTRICAL, ELECTRONIC SYSTEMS

PRIMARY HYDRAULIC POWER SYSTEM

SECONDARY HYDRAULIC POWER SYSTEM

HYDRAULIC COMMAND SYSTEM

HIGH-FLOW HYDRAULIC POWER SYSTEM

ELECTRICAL POWER SYSTEM

LIGHTING SYSTEM

ELECTRONIC SYSTEM

FAULT CODES

ENGINE AND PTO IN

ENGINE

FUEL AND INJECTION SYSTEM

AIR INTAKE SYSTEM

ENGINE COOLANT SYSTEM

STARTING SYSTEM

TRANSMISSION, DRIVE AND PTO OUT

TRANSMISSION Hydrostatic

AXLES, BRAKES AND STEERING

Final drive

Final drive Hydraulic drive

STEERING Mechanical

PARKING BRAKE Hydraulic

WHEELS AND TRACKS Tracks

WHEELS AND TRACKS Wheels

FRAME AND CAB

FRAME Primary frame

SHIELD

USER CONTROLS AND SEAT

USER CONTROLS AND SEAT Operator seat

USER PLATFORM

ENVIRONMENT CONTROL Heating system

ENVIRONMENT CONTROL Air-conditioning system

SAFETY SECURITY ACCESSORIES Safety

FRAME POSITIONING

STABILISING Ballasting

TOOL POSITIONING

LIFTING

TILTING

LEVELLING

SECONDARY FUNCTIONS Hydraulic

HITCH AND WORKING TOOL

BOOM Lift

ARM TOOL ATTACHMENT Tilt

SINGLE ARM Lift

SINGLE ARM TOOL ATTACHMENT Tilt

EXCAVATING AND LANDSCAPING

DIGGING Non-articulated digging tools

CARRYING Unarticulated tools

COUPLING Mechanical coupling

Code:

OPERATORS MANUAL

1 GENERAL INFORMATION

Note to the Owner

Right, left, front and rear of the machine

Identification numbers

Machine components

2 SAFETY INFORMATION

Signal word definition

Safety rules

Decal information

Safety decals

Utility safety

Operator precautions

Proper entry and exit

Starting and stopping precautions

Seat belt precautions

Specific precautions to this machine

Operating precautions

Maintenance precautions

Fuel handling precautions

Burn prevention

Fire extinguisher

Hazardous chemicals

Transporting precautions

Electro-Magnetic Compatibility (EMC)

Roll Over Protective Structure (ROPS)

Welding on the machine

Mechanical lift arm lock procedure - radial lift machines

Mechanical lift arm lock procedure - vertical lift machines

No engine power - lift arm down control

Emergency exit

3 CONTROLS/INSTRUMENTS

ACCESS TO OPERATOR'S PLATFORM

Door latches, cab

Window glass, cab

Windshield wiper and washer controls

Cab air louvers

OPERATOR'S SEAT

Standard seat

Mechanical suspension seat

Air seat

Seat belt

MECHANICAL HYDRAULIC CONTROLS

Steering and travel

Moving the machine

Turning the machine

Lift arm and bucket controls

Hand controls

Foot pedals

ELECTRO HYDRAULIC CONTROLS

Control pattern overview

Standard H control pattern

Standard ISO control pattern

H control pattern steering and travel

Left hand control lever

Right hand control lever

Moving the machine

Turning the machine

H control pattern lift arm and bucket controls

Lift arm raise/lower control

Bucket curl/dump control

ISO control pattern steering and travel

Moving the machine

Turning the machine

Lift arm and bucket controls

CONTROL HANDLES

Switch configurations

Two speed function

AUXILIARY HYDRAULICS

Standard auxiliary hydraulics

High flow auxiliary hydraulics

Enhanced high flow auxiliary hydraulics

INSTRUMENT CLUSTER

Electronic instrument cluster (EIC)

Advanced instrument cluster (AIC)

Instrument cluster

Left column switch identification

ISO or H pattern control switch

Machine lights

Telematics

4 OPERATING INSTRUCTIONS

COMMISSIONING THE UNIT

Operating Instructions

STARTING THE UNIT

Engine operation

Throttle

STOPPING THE UNIT

Parking the machine and stopping the engine

Operating in extreme temperatures

Booster battery procedure

MOVING THE UNIT

Machine operation

5 TRANSPORT OPERATIONS

SHIPPING TRANSPORT

Transporting the machine

RECOVERY TRANSPORT

Moving a disabled machine

6 WORKING OPERATIONS

GENERAL INFORMATION

Mechanical attachment mounting systems

Hydraulic attachment mounting systems

Field operation

7 MAINTENANCE

GENERAL INFORMATION

General safety before you service

Lubrication analysis program

Plastic and resin parts

Ecology and the environment

Tilting operator's compartment forward

Machine cleaning

Window removal and cleaning

Cab door removal and installation

Battery safety - check and cleaning

Fire extinguisher

Biodiesel fuel

Engine hourmeter

Wheels and tires

Fluids and lubricants

Lubrication and maintenance access

Fuses and relays

MAINTENANCE CHART

Maintenance Chart

Maintenance procedures

Clean tracks and components

Engine and hydraulic coolers

Engine coolant reservoir level check

Engine oil

Lift arm, pivot points, coupler pins and cylinder pins

Hydraulic system

Seat belt, lap bar and seat interlock operation check

Alternator and air conditioning compressor (if equipped) belt tension

Cab intake filter

Roll Over Protective Structure (ROPS) mechanism and hardware check

Engine oil and filter

Final drive - Drain fluid

Radiator coolant level check

Fuel filter

In line fuel filter

Drive chain tension check

Primary fuel filter

Hydraulic oil filter

Final drive chain tank oil

Air cleaner elements

Hardware - loose or damaged

Hydraulic fluid

Radiator drain and flush

Final drive chain tank oil

STORAGE

Storing the machine

8 TROUBLESHOOTING

FAULT CODE RESOLUTION

Error code index

9 SPECIFICATIONS

General specification

OTHERAttachments

Last edited by a moderator: