- If you download this document, you will be lost 0 Beer

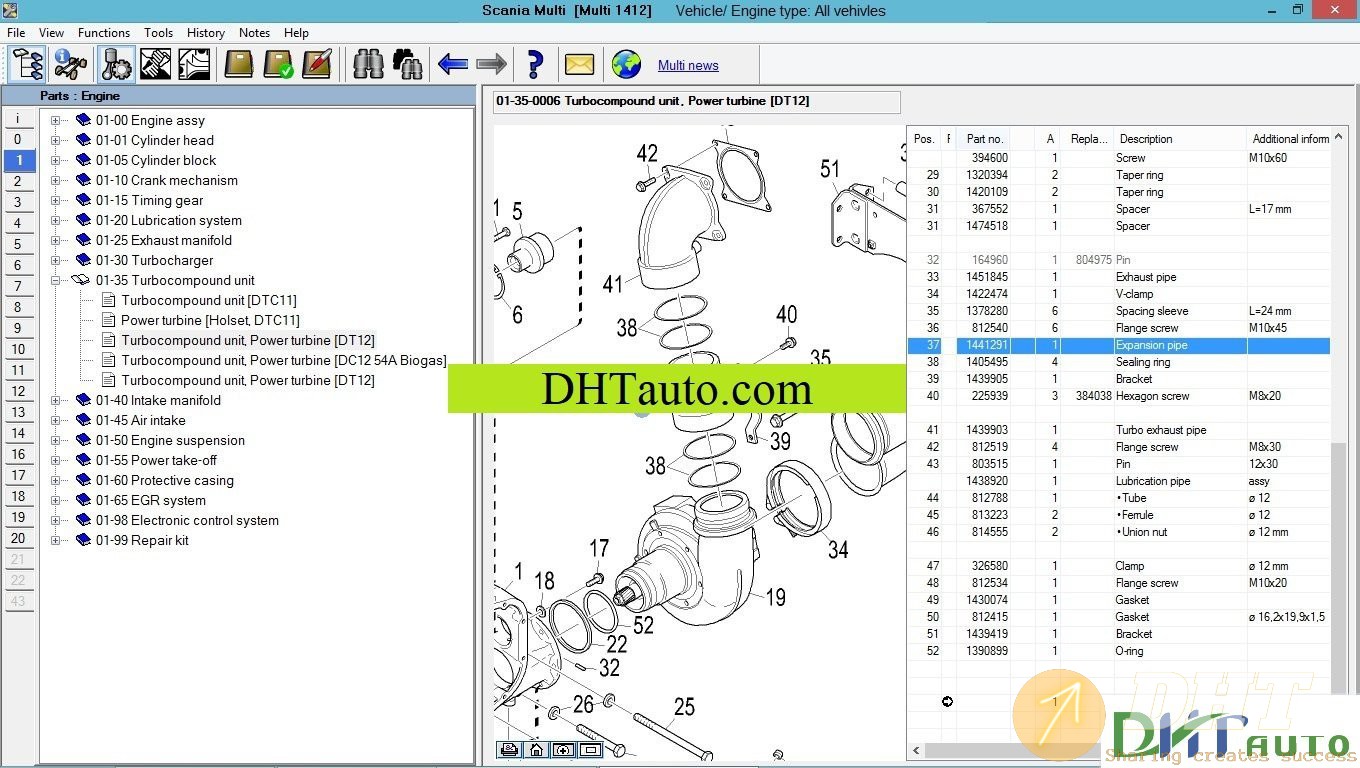

Scania Multi Full [12.2014]

Size: 6,45Gb

Languages: English, Italian

Type: Spare parts Catalog & Service Information

Win: WinXP, Windows7, WIN8

Year: 11.2014

DVD1 & DVD2

Spare parts Catalog & Service Information for Scania Trucks.

1st WEB Release

The program SCANIA placed on 2 DVDs and the chassis, rules of accommodation of a saddle and axes contains the information on spare parts, accessories, and also rules of change and updating, calculation of loading on a frame, etc.

Scania Multi contains the information on spare parts, accessories for Scania cars and buses. All data is presented since 1985 for trucks, chassis-P, GR, T, 3, 4, 5 buses and F-Series, K-, N-series SCANIA, for all regions (different equipment and performance). Contains manuals and repair times.

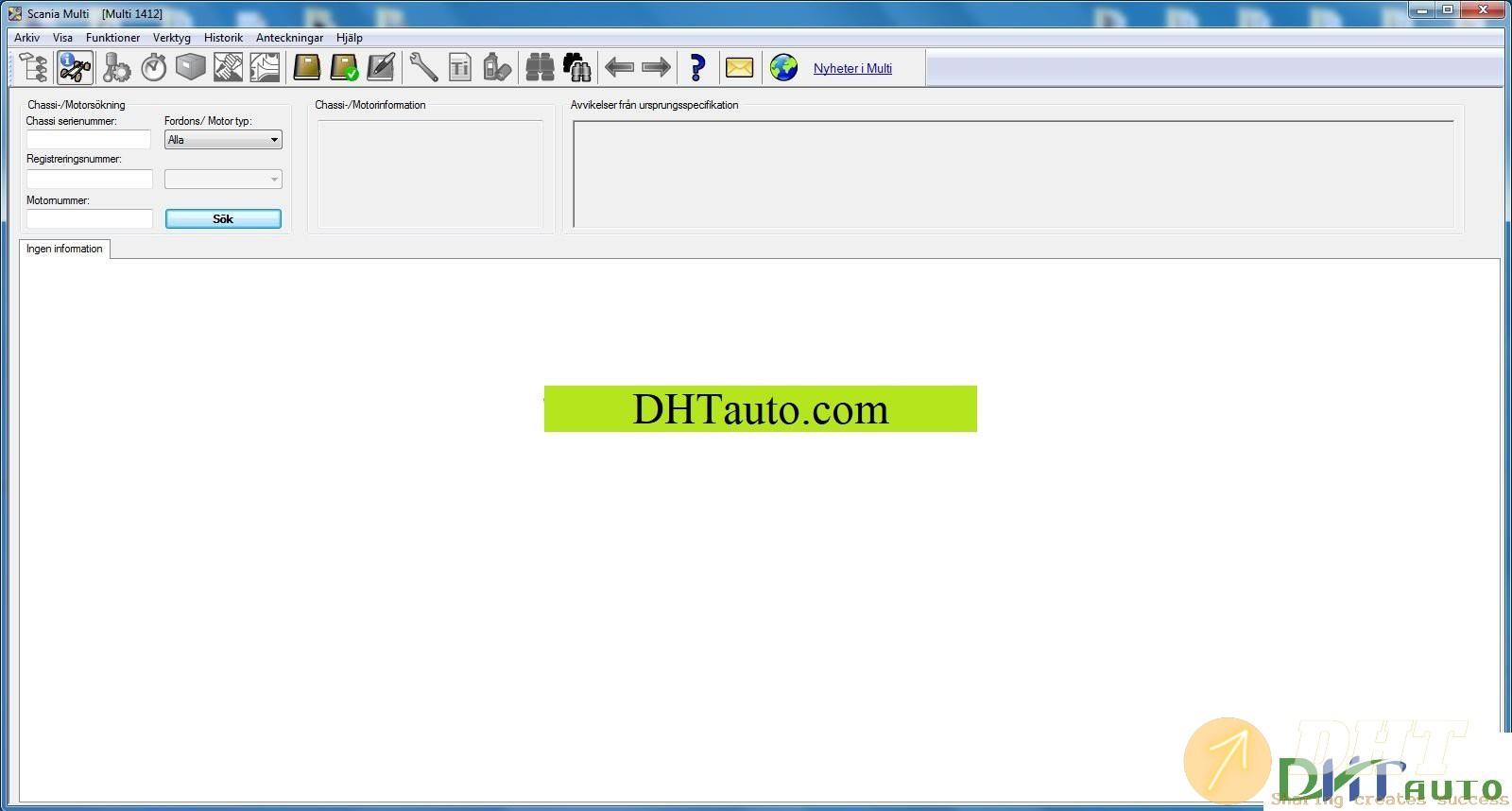

Scania Multi is one of the most advanced workshop information systems on the market. Using the chassis number, it is possible to individually tailor all the information needed to carry out servicing, fault-tracing and repairs on each individual vehicle, thus enhancing the quality and precision of the workshop's operations. At the same time, the customer benefits from a shorter standstill time.

Time savings and better quality for the customer

• Precision: the right parts, times and operations from the very outset.

• Easily accessible information: quick searching, only relevant information.

• Rapid response: cost estimate at the first contact.

• Many languages: information in 9 languages increases precision and speed.

• Simple updating: only current information is found in the system.

• The workshop of the future: everyone at the Scania workshop has access to the information in Scania Multi, which makes for a flexible organisation.

• Local modifications are simple: Scania Multi is structured so that special adaptations can be integrated for each specific market.

Here is a typical sequence of events when visiting a Scania workshop which uses Scania Multi:

A driver observes a brake fault on his truck and drives to a Scania workshop. With the help of the chassis number, the customer receptionist calls up the truck's specification and uses Scania Multi to determine the work which needs to be carried out. The customer receptionist can thus immediately offer the customer a time and cost estimate.

The mechanic who takes on the job looks up Scania Multi to find out how it should be tackled on this particular truck, and verifies exactly which parts will be needed for this chassis number. The system despatches an order to the parts store, which fetches the relevant parts. The truck is repaired and the Scania Multi system then automatically produces the necessary documentation for invoicing the customer.

All this information is easily accessible to all users of Scania Multi. The system opens the door to a restructuring of workshop operations. The mechanic can if necessary act as a customer receptionist and can even handle invoicing and other follow-up processes.

EXPIRE FIXED Method :

1. Open MS Access 2003 or 2007

1a. If you don't want to install Office, get MDBPLUS from http://www.alexnolan.net/software/mdb_viewer_plus.htm

2. Open file "Multi.mdb" from installation folder: C:\MultiDat\Catalog\Multi.mdb

3. Open table "MultiProParameter"

4. Open parameter "PROD_STAMP" change to: *').$,#(

Size: 6,45Gb

Languages: English, Italian

Type: Spare parts Catalog & Service Information

Win: WinXP, Windows7, WIN8

Year: 11.2014

DVD1 & DVD2

Spare parts Catalog & Service Information for Scania Trucks.

1st WEB Release

The program SCANIA placed on 2 DVDs and the chassis, rules of accommodation of a saddle and axes contains the information on spare parts, accessories, and also rules of change and updating, calculation of loading on a frame, etc.

Scania Multi contains the information on spare parts, accessories for Scania cars and buses. All data is presented since 1985 for trucks, chassis-P, GR, T, 3, 4, 5 buses and F-Series, K-, N-series SCANIA, for all regions (different equipment and performance). Contains manuals and repair times.

Scania Multi is one of the most advanced workshop information systems on the market. Using the chassis number, it is possible to individually tailor all the information needed to carry out servicing, fault-tracing and repairs on each individual vehicle, thus enhancing the quality and precision of the workshop's operations. At the same time, the customer benefits from a shorter standstill time.

Time savings and better quality for the customer

• Precision: the right parts, times and operations from the very outset.

• Easily accessible information: quick searching, only relevant information.

• Rapid response: cost estimate at the first contact.

• Many languages: information in 9 languages increases precision and speed.

• Simple updating: only current information is found in the system.

• The workshop of the future: everyone at the Scania workshop has access to the information in Scania Multi, which makes for a flexible organisation.

• Local modifications are simple: Scania Multi is structured so that special adaptations can be integrated for each specific market.

Here is a typical sequence of events when visiting a Scania workshop which uses Scania Multi:

A driver observes a brake fault on his truck and drives to a Scania workshop. With the help of the chassis number, the customer receptionist calls up the truck's specification and uses Scania Multi to determine the work which needs to be carried out. The customer receptionist can thus immediately offer the customer a time and cost estimate.

The mechanic who takes on the job looks up Scania Multi to find out how it should be tackled on this particular truck, and verifies exactly which parts will be needed for this chassis number. The system despatches an order to the parts store, which fetches the relevant parts. The truck is repaired and the Scania Multi system then automatically produces the necessary documentation for invoicing the customer.

All this information is easily accessible to all users of Scania Multi. The system opens the door to a restructuring of workshop operations. The mechanic can if necessary act as a customer receptionist and can even handle invoicing and other follow-up processes.

EXPIRE FIXED Method :

1. Open MS Access 2003 or 2007

1a. If you don't want to install Office, get MDBPLUS from http://www.alexnolan.net/software/mdb_viewer_plus.htm

2. Open file "Multi.mdb" from installation folder: C:\MultiDat\Catalog\Multi.mdb

3. Open table "MultiProParameter"

4. Open parameter "PROD_STAMP" change to: *').$,#(

Attachments

Last edited: