- If you download this document, you will be lost Beer

Komatsu Mobile Crusher Br380jg-1eo Shop Manual

Table of contents 1

00 Index and foreword

Index SEN01343-03

Composition of shop manual....................................................................................................... 2

Table of contents ......................................................................................................................... 4

Foreword and general information SEN01344-00

Safety notice............................................................................................................................... 2

How to read the shop manual ..................................................................................................... 7

Explanation of terms for maintenance standard.......................................................................... 9

Handling electric equipment and hydraulic component............................................................... 11

How to read electric wire code .................................................................................................... 23

Precautions when carrying out operation.................................................................................... 26

Method of disassembling and connecting push-pull type coupler ............................................... 29

Standard tightening torque table ................................................................................................. 32

Conversion table ......................................................................................................................... 36

01 Specification

Specification and technical data SEN01346-00

Specification dimension drawings ............................................................................................... 2

Specifications .............................................................................................................................. 3

Weight table ............................................................................................................................... 5

Table of fuel, coolant and lubricants ............................................................................................ 6

10 Structure, function and maintenance standard

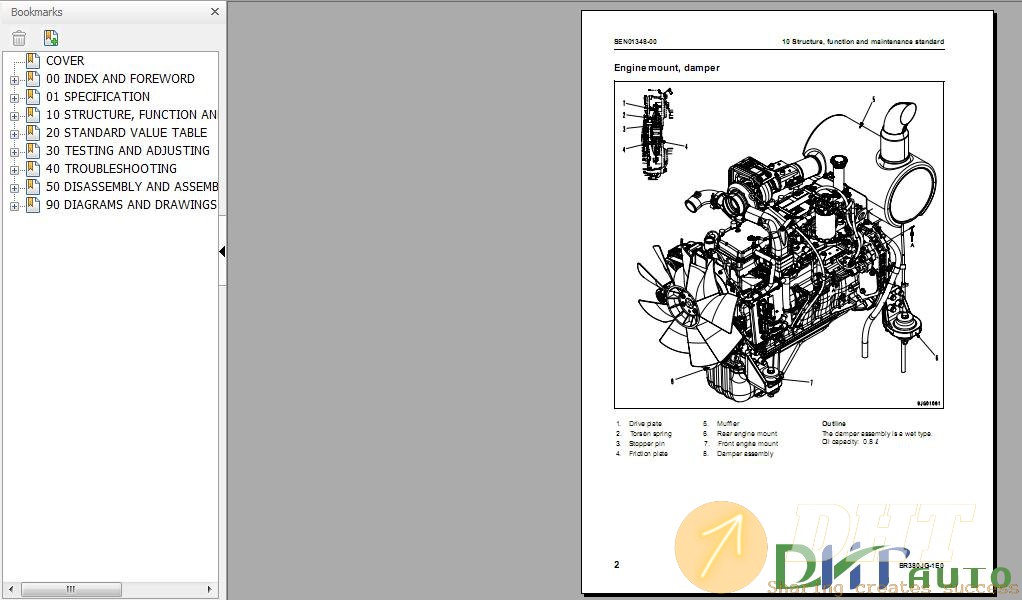

Engine and cooling system SEN01348-00

Engine mount, damper ................................................................................................................ 2

Radiator, oil cooler and aftercooler.............................................................................................. 3

Power train SEN01349-00

Power train ................................................................................................................................. 2

Drive system for components...................................................................................................... 3

Final drive................................................................................................................................... 4

Sprocket ..................................................................................................................................... 6

Undercarriage and frame SEN01350-00

Track frame and recoil spring ...................................................................................................... 2

Idler ............................................................................................................................................ 4

Carrier roller ............................................................................................................................... 6

Track roller.................................................................................................................................. 7

Track shoe.................................................................................................................................. 8

Hydraulic sysmtem, Part 1 SEN01351-00

Hydraulic piping drawing ............................................................................................................. 2

Hydraulic tank and hydraulic oil filter........................................................................................... 3

Hydraulic pump ........................................................................................................................... 4

Hydraulic system, Part 2 SEN01352-00

Control valve ............................................................................................................................... 2

Self pressure reducing valve....................................................................................................... 10

CLSS.......................................................................................................................................... 15

Functions and operation by valve................................................................................................ 19

00 Index and foreword SEN01343-03

BR380JG-1E0 5

Hydraulic system, Part 3 SEN01353-00

Crusher motor ............................................................................................................................. 2

Grizzly feeder motor.................................................................................................................... 6

Conveyor motor.......................................................................................................................... 7

Travel motor ............................................................................................................................... 8

Valve control............................................................................................................................... 16

Solenoid valve............................................................................................................................ 26

EPC valve .................................................................................................................................. 28

Electromagnetic selector valve ................................................................................................... 32

Hydraulic cylinder....................................................................................................................... 34

Work equipment SEN01354-00

Grizzly feeder semiautomatic system ......................................................................................... 2

Abnormal load stop system......................................................................................................... 3

Primary belt conveyor ................................................................................................................. 4

Grizzly feeder .............................................................................................................................. 8

Crusher ...................................................................................................................................... 9

Crusher tooth tip adjustment system........................................................................................... 14

Vibrator....................................................................................................................................... 17

Electrical system SEN01355-00

Engine control ............................................................................................................................. 2

Work equipment and pump controller ......................................................................................... 12

Electronic control system............................................................................................................ 15

Machine monitor system ............................................................................................................. 28

Sensor........................................................................................................................................ 54

20 Standard value table

Standard service value table SEN02288-00

Standard value table for engine .................................................................................................. 2

Standard value table for chassis ................................................................................................. 3

30 Testing and adjusting

Testing and adjusting, Part 1 SEN02303-00

Tools for testing, adjusting, and troubleshooting ......................................................................... 3

Measuring engine speed............................................................................................................. 6

Measuring intake air pressure (boost pressure).......................................................................... 7

Checking exhaust gas color ........................................................................................................ 8

Adjusting valve clearance ........................................................................................................... 9

Measuring compression pressure ............................................................................................... 11

Measuring blow-by pressure ....................................................................................................... 13

Measuring engine oil pressure .................................................................................................... 14

Handling fuel system parts.......................................................................................................... 15

Releasing residual pressure from fuel system ............................................................................ 15

Measuring fuel pressure.............................................................................................................. 16

Measuring fuel return rate and leakage ...................................................................................... 18

Bleeding air from fuel circuit........................................................................................................ 20

Checking fuel circuit for leakage ................................................................................................. 22

Checking and adjusting track shoe tension................................................................................. 23

Measuring and adjusting oil pressure in work equipment and travel circuits .............................. 25

Measuring control circuit basic pressure..................................................................................... 29

Measuring and adjusting oil pressure in pump PC control circuit ............................................... 30

Measuring and adjusting oil pressure in pump LS control circuit ................................................ 33

Measuring solenoid valve output pressure.................................................................................. 37

Measuring PPC valve output pressure........................................................................................ 40

Measuring oil leakage ................................................................................................................. 41

Bleeding air from each part ......................................................................................................... 42

Testing travel deviation................................................................................................................ 45

Adjusting mirrors ......................................................................................................................... 46

SEN01343-03 00 Index and foreword

6 BR380JG-1E0

Testing and adjusting, Part 2 SEN02304-00

Special functions of machine monitor.......................................................................................... 2

Testing and adjusting, Part 3 SEN02305-01

Check and adjustment of jaw crusher ......................................................................................... 2

Check and adjustment of outlet clearance .................................................................................. 4

Adjusting tension of crusher drive V-belt ..................................................................................... 37

Check and adjustment of primary conveyor ................................................................................ 38

Inspection and maintenance of magnetic separator.................................................................... 44

Check and adjustment of muck discharge conveyor................................................................... 46

List of companies which handles radio controllers ...................................................................... 48

Handling voltage circuit of engine controller................................................................................ 49

Procedure for turning on KOMTRAX terminal ............................................................................. 50

KOMTRAX terminal lamp indications .......................................................................................... 53

Preparation work for troubleshooting for electrical system.......................................................... 56

Procedure for testing diodes ....................................................................................................... 60

40 Troubleshooting

Failure code table and fuse locations SEN02088-00

Failure code table........................................................................................................................ 2

Fuse locations ............................................................................................................................. 6

General information on troubleshooting SEN02089-01

Points to remember when troubleshooting.................................................................................. 2

Sequence of events in troubleshooting ....................................................................................... 3

Checks before troubleshooting.................................................................................................... 4

Classification and procedures of troubleshooting........................................................................ 6

Contents of troubleshooting table................................................................................................ 10

Wiring table for connector pin numbers....................................................................................... 12

T-adapter box and T-adapter table .............................................................................................. 45

Table of contents 1

00 Index and foreword

Index SEN01343-03

Composition of shop manual....................................................................................................... 2

Table of contents ......................................................................................................................... 4

Foreword and general information SEN01344-00

Safety notice............................................................................................................................... 2

How to read the shop manual ..................................................................................................... 7

Explanation of terms for maintenance standard.......................................................................... 9

Handling electric equipment and hydraulic component............................................................... 11

How to read electric wire code .................................................................................................... 23

Precautions when carrying out operation.................................................................................... 26

Method of disassembling and connecting push-pull type coupler ............................................... 29

Standard tightening torque table ................................................................................................. 32

Conversion table ......................................................................................................................... 36

01 Specification

Specification and technical data SEN01346-00

Specification dimension drawings ............................................................................................... 2

Specifications .............................................................................................................................. 3

Weight table ............................................................................................................................... 5

Table of fuel, coolant and lubricants ............................................................................................ 6

10 Structure, function and maintenance standard

Engine and cooling system SEN01348-00

Engine mount, damper ................................................................................................................ 2

Radiator, oil cooler and aftercooler.............................................................................................. 3

Power train SEN01349-00

Power train ................................................................................................................................. 2

Drive system for components...................................................................................................... 3

Final drive................................................................................................................................... 4

Sprocket ..................................................................................................................................... 6

Undercarriage and frame SEN01350-00

Track frame and recoil spring ...................................................................................................... 2

Idler ............................................................................................................................................ 4

Carrier roller ............................................................................................................................... 6

Track roller.................................................................................................................................. 7

Track shoe.................................................................................................................................. 8

Hydraulic sysmtem, Part 1 SEN01351-00

Hydraulic piping drawing ............................................................................................................. 2

Hydraulic tank and hydraulic oil filter........................................................................................... 3

Hydraulic pump ........................................................................................................................... 4

Hydraulic system, Part 2 SEN01352-00

Control valve ............................................................................................................................... 2

Self pressure reducing valve....................................................................................................... 10

CLSS.......................................................................................................................................... 15

Functions and operation by valve................................................................................................ 19

00 Index and foreword SEN01343-03

BR380JG-1E0 5

Hydraulic system, Part 3 SEN01353-00

Crusher motor ............................................................................................................................. 2

Grizzly feeder motor.................................................................................................................... 6

Conveyor motor.......................................................................................................................... 7

Travel motor ............................................................................................................................... 8

Valve control............................................................................................................................... 16

Solenoid valve............................................................................................................................ 26

EPC valve .................................................................................................................................. 28

Electromagnetic selector valve ................................................................................................... 32

Hydraulic cylinder....................................................................................................................... 34

Work equipment SEN01354-00

Grizzly feeder semiautomatic system ......................................................................................... 2

Abnormal load stop system......................................................................................................... 3

Primary belt conveyor ................................................................................................................. 4

Grizzly feeder .............................................................................................................................. 8

Crusher ...................................................................................................................................... 9

Crusher tooth tip adjustment system........................................................................................... 14

Vibrator....................................................................................................................................... 17

Electrical system SEN01355-00

Engine control ............................................................................................................................. 2

Work equipment and pump controller ......................................................................................... 12

Electronic control system............................................................................................................ 15

Machine monitor system ............................................................................................................. 28

Sensor........................................................................................................................................ 54

20 Standard value table

Standard service value table SEN02288-00

Standard value table for engine .................................................................................................. 2

Standard value table for chassis ................................................................................................. 3

30 Testing and adjusting

Testing and adjusting, Part 1 SEN02303-00

Tools for testing, adjusting, and troubleshooting ......................................................................... 3

Measuring engine speed............................................................................................................. 6

Measuring intake air pressure (boost pressure).......................................................................... 7

Checking exhaust gas color ........................................................................................................ 8

Adjusting valve clearance ........................................................................................................... 9

Measuring compression pressure ............................................................................................... 11

Measuring blow-by pressure ....................................................................................................... 13

Measuring engine oil pressure .................................................................................................... 14

Handling fuel system parts.......................................................................................................... 15

Releasing residual pressure from fuel system ............................................................................ 15

Measuring fuel pressure.............................................................................................................. 16

Measuring fuel return rate and leakage ...................................................................................... 18

Bleeding air from fuel circuit........................................................................................................ 20

Checking fuel circuit for leakage ................................................................................................. 22

Checking and adjusting track shoe tension................................................................................. 23

Measuring and adjusting oil pressure in work equipment and travel circuits .............................. 25

Measuring control circuit basic pressure..................................................................................... 29

Measuring and adjusting oil pressure in pump PC control circuit ............................................... 30

Measuring and adjusting oil pressure in pump LS control circuit ................................................ 33

Measuring solenoid valve output pressure.................................................................................. 37

Measuring PPC valve output pressure........................................................................................ 40

Measuring oil leakage ................................................................................................................. 41

Bleeding air from each part ......................................................................................................... 42

Testing travel deviation................................................................................................................ 45

Adjusting mirrors ......................................................................................................................... 46

SEN01343-03 00 Index and foreword

6 BR380JG-1E0

Testing and adjusting, Part 2 SEN02304-00

Special functions of machine monitor.......................................................................................... 2

Testing and adjusting, Part 3 SEN02305-01

Check and adjustment of jaw crusher ......................................................................................... 2

Check and adjustment of outlet clearance .................................................................................. 4

Adjusting tension of crusher drive V-belt ..................................................................................... 37

Check and adjustment of primary conveyor ................................................................................ 38

Inspection and maintenance of magnetic separator.................................................................... 44

Check and adjustment of muck discharge conveyor................................................................... 46

List of companies which handles radio controllers ...................................................................... 48

Handling voltage circuit of engine controller................................................................................ 49

Procedure for turning on KOMTRAX terminal ............................................................................. 50

KOMTRAX terminal lamp indications .......................................................................................... 53

Preparation work for troubleshooting for electrical system.......................................................... 56

Procedure for testing diodes ....................................................................................................... 60

40 Troubleshooting

Failure code table and fuse locations SEN02088-00

Failure code table........................................................................................................................ 2

Fuse locations ............................................................................................................................. 6

General information on troubleshooting SEN02089-01

Points to remember when troubleshooting.................................................................................. 2

Sequence of events in troubleshooting ....................................................................................... 3

Checks before troubleshooting.................................................................................................... 4

Classification and procedures of troubleshooting........................................................................ 6

Contents of troubleshooting table................................................................................................ 10

Wiring table for connector pin numbers....................................................................................... 12

T-adapter box and T-adapter table .............................................................................................. 45

Attachments

Last edited by a moderator: